Key Takeaways

- Print texture depends on ink volume, curing control, and how the fabric surface reacts during production.

- Comfort during wear changes with placement, thickness, and how prints move with the body.

- Fabric weight and weave influence how prints age after washing and repeated daily use.

- Matching surface feel to use case helps avoid stiffness, cracking, and uneven wear over time.

Introduction

Comfort during long wear comes down to ink behaviour. The way ink settles, cures, and bonds with fabric decides whether a shirt stays flexible, softens over time, or stiffens after repeated washing. Flat applications sit quietly on the surface, layered prints add height, and curing fixes firmness in place. Each choice leaves a physical trace that wearers notice.

Consistency starts to matter once quantities grow. Runs that demand the same surface feel from first piece to last often turn to silkscreen printing in Singapore. Fabric selection influences absorption and curing response, which explains reliance on partners who understand material behaviour, including a shirt supplier in Singapore familiar with production demands.

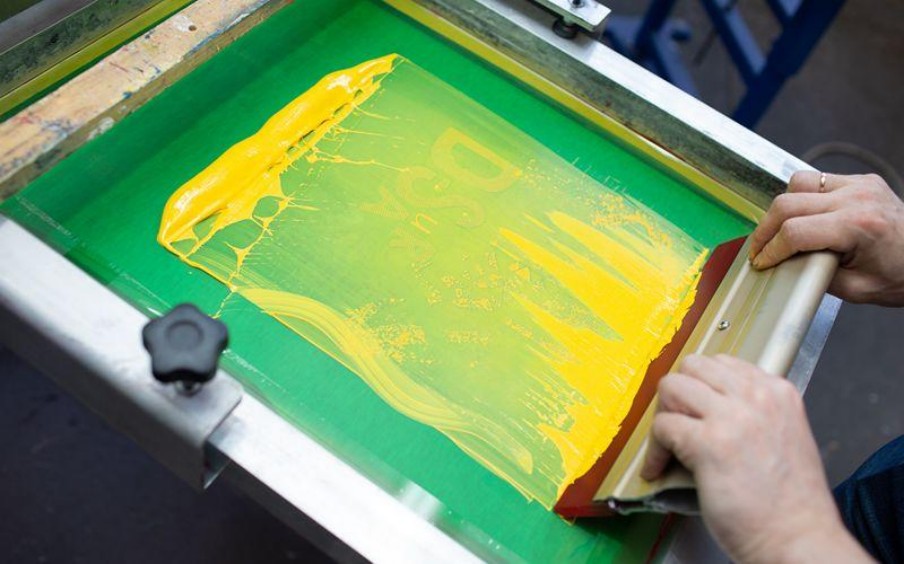

What Shapes Texture in Silkscreen Printing

Ink Thickness and Layering

Surface feel shifts with ink volume. Light passes keep prints flexible and low-profile, while additional layers introduce firmness and height. Artwork style guides the balance, since bold shapes tolerate heavier deposits and softer visuals rely on thinner layers to maintain movement.

Fabric weight changes how ink behaves during curing. Lighter knits absorb and spread ink differently from heavier jerseys. Matching knit density with ink load becomes easier when working with a shirt supplier in Singapore experienced in silkscreen workflows, keeping curing even and predictable.

Fabric Interaction and Hand Feel

Hand feel depends on weave and fibre. Smooth cotton offers an even base that keeps edges clean, while textured weaves create subtle variation beneath the ink. Comfort enters the decision early for garments meant for repeated wear, where silkscreen printing in Singapore appears frequently.

Placement alters sensation during movement. Prints across bending zones feel different from marks near seams or hems. Aligning fabric behaviour with print size and positioning often involves coordination with a shirt supplier in Singapore to avoid irritation or stiffness.

Why Feel Matters in Printed Apparel

Comfort During Regular Wear

Movement reveals surface differences. Raised prints draw attention at elbows, shoulders, or across the torso, while flatter finishes fade into the fabric during motion. Apparel used for uniforms, events, or retail settings benefits from ink application that supports flexibility rather than resisting it.

Comfort remains predictable when production variables stay controlled. Once ink, fabric, and curing align, repeatable outcomes follow during silkscreen printing in Singapore. Wearability stays consistent across sizes and cuts when print style pairs with garments supplied by a dependable shirt supplier in Singapore.

Visual Depth Without Excess Detail

Texture adds contrast without relying on colour changes or complex artwork. Ink edges catch light differently from fabric, giving simple graphics presence. Minimal designs use surface variation to avoid appearing flat.

Many projects rely on silkscreen printing in Singapore to let texture carry visual weight. Consistency across production runs depends on garment quality supplied by a shirt supplier in Singapore.

Practical Considerations for Print Planning

Wash Performance and Longevity

Use over time exposes early decisions. Thicker prints hold shape longer, while thinner layers soften and blend into fabric through wear. Curing quality and fabric compatibility determine whether prints crack, fade, or stabilise.

Garment selection influences post-wash behaviour. Fewer surprises appear after distribution when wash performance is understood by a shirt supplier in Singapore. Proper curing and fabric pairing help preserve surface feel and appearance.

Matching Texture to Purpose

Use case drives surface choice. Promotional shirts favour softer finishes that disappear during wear, while statement pieces accept heavier ink for presence. Options that suit both needs exist when planning with silkscreen printing in Singapore.

Decisions hold up better when texture aligns with intended use. Input from a shirt supplier in Singapore experienced in event, retail, and uniform apparel supports planning that lasts beyond first wear.

Conclusion

Texture affects reuse, comfort, and long-term appearance. Control over surface feel and durability comes from aligning fabric choice, ink application, and curing during silkscreen printing. Careful planning keeps results consistent across production.

Contact MonsterPrints today to discuss silkscreen printing options that match fabric choice, texture preference, and intended use.